CTIS

Central Tire Inflation System

Tire pressures are critical if you want to get the best from your machinery.

Central Tire Inflation Systems (CTIS) will allow you to maintain the correct tire pressure for varying loads, differential speeds, changing terrain and road conditions. This will not only optimize your tire foot print, which will save you time, but it will also save in fuel, increase your traction, minimize ground compaction and assist yields, which, in turn, will reduce expenses and maximize profits.

What is Central Tire Inflation?

Central Tire Inflation System lets you quickly and easily adjust and maintain the correct tire pressures. Tire pressure can be adjusted for varying loads, different speeds, and changing road and field conditions, and can all be done with the touch of a button. This will work in your favour by saving you time, all the while reducing your operating costs, protecting your soil and fields, increasing yields and maximizing the output of your machinery.

Benefits of Central Tire Inflation

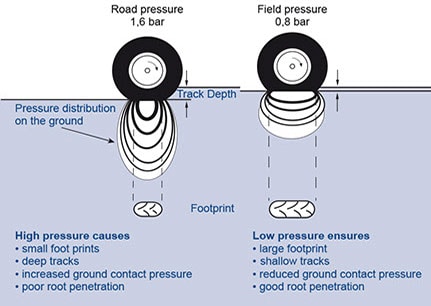

- Reduced fuel consumption of the towing tractor in the field and on the road (10 % – 15 %)

- Example: 5 cm depth of track = + 10 % diesel consumption

- Reduced rolling resistance in the field and on the road

- Higher ride stability on the road at higher speeds

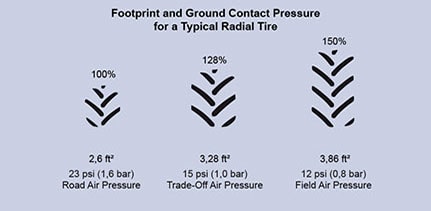

- Reduction of the track depth caused through bigger footprint of the tyre

- Strong increase of towing force due to better interlocking of the tyre profile with the ground

- None/reduced soil compaction

- Higher yields

- Self cleaning effect of the profile through flexing tyres

- No tyre damages/less tyre wear

How does CTIS work

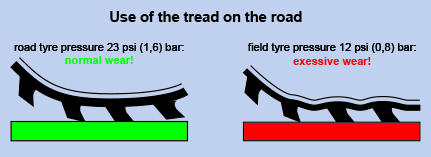

In the field, when the pressure in the tire is lower, it will spread the weight of the machine out over a greater tire foot print. This will help reduce the soil compaction, reduce the rolling resistance and also reduce fuel consumption. The low pressure also helps prevent wheel slips and maximizes the grips of the tire. When the machine is transitioned to the road, the higher pressure in the tire give stability, increases fuel efficiency and minimizes tire wear.

This can all be achieved efficiently from the comfort of the driver’s seat while on the road or in the field, thanks to CTIS.

This can all be achieved thanks to the unique PTG-patented CTIS dual line design features. These lines are pneumatically controlled check valves located on the wheel rims, that are only activated and opened when the lines are pressurized during active tire adjustments and monitoring. Once the correct pressures is reached, the system shuts off air, and the check valves close. Check valves on the wheel rims are beneficial to help minimize component wear as it has zero air pressure in the circuit, and they also act as a safety, should a line fail.

Field pressure and road pressure presets can be created in accordance with the tire manufacture recommendations. This means it takes just a few minutes to inflate or deflate tires, and is suitable for all tractors, trailers and agricultural machinery with tires.

Installation

CTIS can be installed on new or existing machinery, and we offer installation options to suit your requirements.

Just like our tailored CTIS, we offer installation options that suit your requirements.

Considering trading your machinery in the future? but want the benefits of using CTIS now? The system can be removed from your current machine and installed on suitable new equipment at the time of purchase preserving your investment.

For more information about the components we use and CTIS products available, check out our products page.