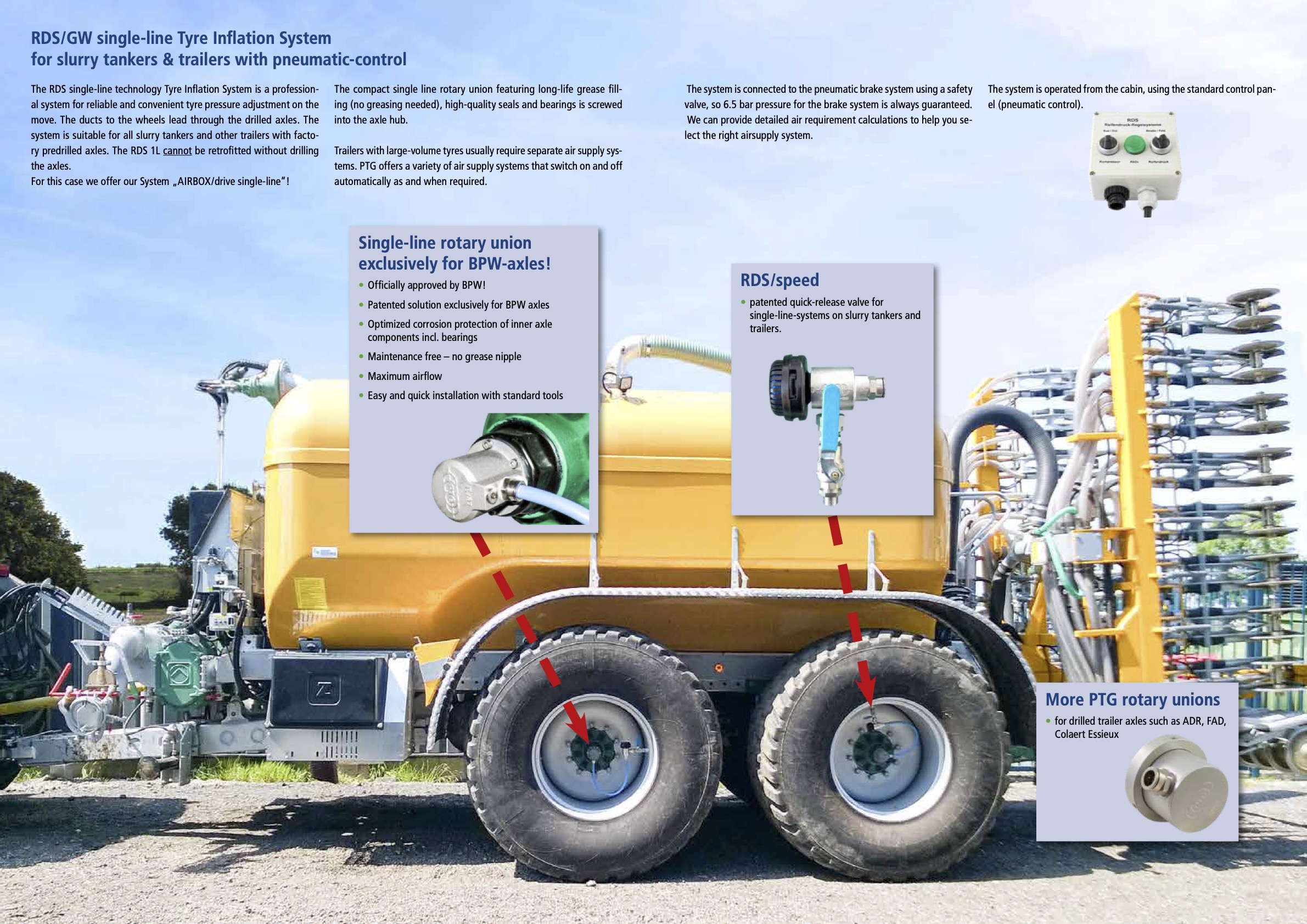

The RDS tire inflation system 1 line technology is a proven and reliable system for comfortably adjusting tire pressure while the vehicle is moving. The lines are led through the bored axles. This system is suited for all slurry tankers and other drawn vehicles with axles that came pre-bored from the factory. A retrofit with the RDS 1L is not possible unless the axles come pre-bored since subsequent boring of the axle would result in voiding the axle’s operating permit!

Air is led to the tire through the axle. The compact 1 line rotary joint is screwed into the axle hub. This rotary joint is unique for its lifetime grease filling (tedious refillings become no longer necessary), high-quality rotary seals and ball bearings. The sealing system for sealing the grease cap was developed in cooperation with BPW. A ball valve is mounted in the rim that must be closed by hand after the vehicle has been parked.

Due to the large volume of the tires on the vehicle, the use of separate/additional air supply systems is usually necessary. PTG offers various air supply systems that turn on and off automatically as needed.

In selecting the right air supply system for you we will gladly help you with one of our detailed air requirement calculations.

The system is connected via a safety valve to the air brake system so that 6.5 bar (94 psi) of pressure supply in the air brake reservoir is guaranteed at all times.

Operating the system is done from the cab using the control console of the pneumatic control.

311 Ingersoll St S,

Ingersoll, Ontario N5C 3R5

Canada

(226) 387-0054

Powered by In Motion Brands